-

Product Center

contact us

Cixi High New(GAOXIN) Sealing Material Co., Ltd.

Address: No. 699, Cibei Avenue, Cidong Binhai District, Longshan Town, Cixi City

Tel: 0574-63225692

0574-63225685Fax: 0574-63972521

product detailscurrent location : home > Product Center > product detailsUltra low temperature resistant spiral wound gasket

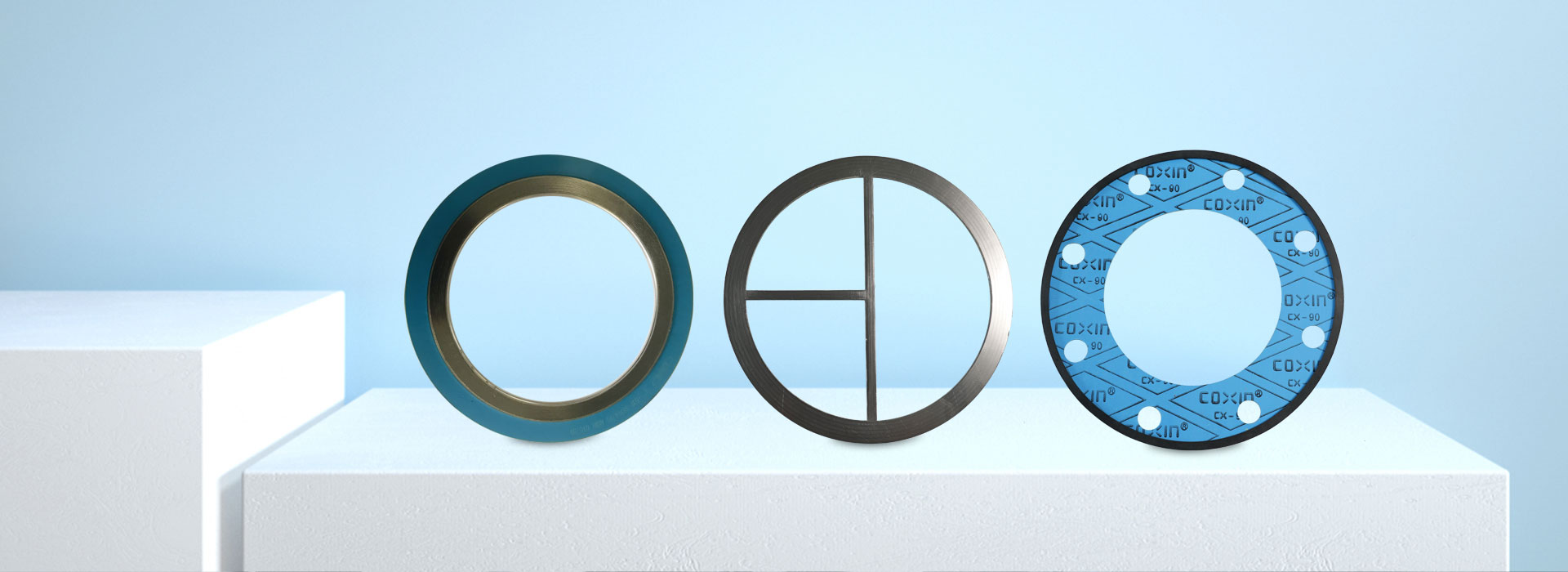

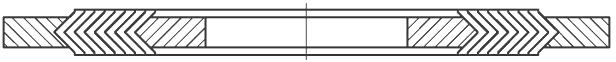

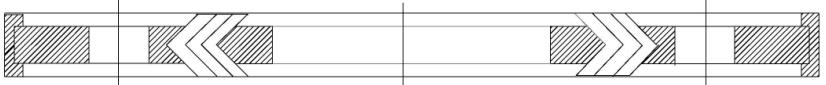

Spiral wound gasket is made of V-shaped or W-shaped metal belt and non-metallic filler belt alternately overlapped, spiral wound, and end spot welding, and reinforcement ring can be added according to working conditions.

It is applicable to a wide range of working conditions. It can withstand high temperature, high pressure and the use conditions under ultra-low temperature or vacuum. By changing the material combination of the gasket, the chemical corrosion problem of the gasket caused by various media can be solved. Strong stress compensation capability. The sealing performance is stable and reliable at the station with frequent temperature and pressure fluctuations. The sealing performance is excellent. The requirements for the surface accuracy of the flange in contact with the gasket are not high. It is easy to install, and the pre tightening pressure of the gasket is low& nbsp;

- Product Description

Spiral wound gasket is made of V-shaped or W-shaped metal belt and non-metallic filler belt alternately overlapped, spiral wound, and end spot welding, and reinforcement ring can be added according to working conditions.

It is applicable to a wide range of working conditions. It can withstand high temperature, high pressure and the use conditions under ultra-low temperature or vacuum. By changing the material combination of the gasket, the chemical corrosion problem of the gasket caused by various media can be solved. Strong stress compensation capability. The sealing performance is stable and reliable at the station with frequent temperature and pressure fluctuations. The sealing performance is excellent. The requirements for the surface accuracy of the flange in contact with the gasket are not high. It is easy to install, and the pre tightening pressure of the gasket is low& nbsp;

Type

Code

Cross section

constitute

Apply to the flange

Basic type

A

It is formed by winding metal belt and filler belt

TG

With inner ring

B

Add metal inner ring on the basis of basic type

MF

With centering ring

C

Sleeve the outer ring on the basis of the basic type

FF or RF

Type with inner ring and centering ring

D

Add inner ring on the basis of centering ring type

FF or RF

Environmentally friendly

E

On the basis of the inner ring and centering ring type, the sealing ring is sleeved on the outer edge of the centering ring

FF

Performance table of non-metallic filler strip materials

Material

Temperature ℃

Pressure MPa

Medium

Abbreviation

Color Code

Flexible graphite

-196~650

oxidizing medium is not higher than 600)

0~25

High temperature, weak corrosivity

F.G.

Gray stripe

teflon

-196~260

0~10

Strong corrosivity

PTFE

White stripe

Non asbestos fibre

-50~250

0~10

General air tightness

NA

No Color

ceramic fiber

-150~1090

0~10

High temperature, poor air tightness

CER

Light green

Metal strip material performance table

Material

Temperature ℃

Abbreviation

Color Code

304SS

-196~760

304

Yellow

304LSS

-196~450

304L

No Color

316LSS

-196~450

316L

Green

347SS

-195~815

347

Blue

321SS

-196~815

321

Turquoise

Monel400

-130~815

MON

Orange

Titanium(T2)

-195~1090

TI

Purple

Duplex stainless steel2205

-40~300

2205

No Color

Inconel600

-100~1090

INC 600

Gold

Inconel625

-100~1090

INC 625

Gold

Inconel800

-100~870

IN 800

White

- Product Description